01

Marine Equipment Repair

Specialized repair and inspection services for key marine equipment.

We diagnose and restore navigation, communication, and safety systems.

Equipment We Repair

-

Navigation Equipment Repair

We precisely diagnose failures in key navigation devices such as radar, GPS, and AIS and restore normal operation.

We resolve issues like unstable signals, display abnormalities, and sensor errors on-site. -

Communication Equipment Repair

We provide repair and performance inspection for onboard and external communication equipment (VHF, MF/HF, satellite communications).

We accurately identify and restore issues such as low sensitivity and TX/RX failures. -

Safety Equipment Repair

We repair and function-test safety-related equipment such as alarms, gas detectors, and fire-fighting systems. Based on inspection procedures compliant with international regulations, we stabilize preventive safety systems.

-

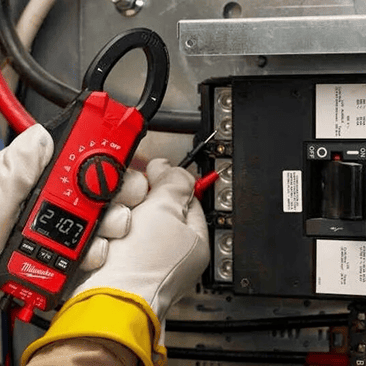

Instrumentation & Sensor Repair

We repair and function-test instrumentation and sensor devices used for monitoring and safety. Based on inspection procedures compliant with international regulations, we stabilize preventive safety systems.

02

Engine & Machinery Inspection

Professional solutions for engine and machinery inspection.

We provide preventive maintenance services based on precise diagnostics.

Inspection & Maintenance Services

-

Main Engine Inspection

-

Auxiliary Engine & Generator Maintenance

-

Pump & Compressor Inspection

-

Overhaul Work

Diagnostic Technology

-

Vibration Analysis

Using vibration analysis equipment, we precisely detect abnormal signs in engines and rotating machinery.

We identify major failure factors in advance—bearing wear, imbalance, shaft alignment issues—extending equipment life and preventing unexpected shutdowns. -

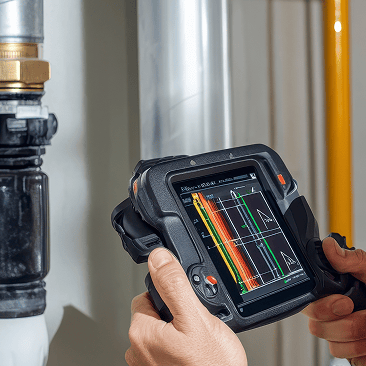

Thermal Imaging

We use thermal cameras to accurately identify overheated areas and electrical/mechanical overload.

We detect internal heat issues early—hard to see with the naked eye—to prevent accidents and equipment damage. -

Oil Analysis

We analyze oil samples for wear particles, viscosity changes, and contaminants to accurately diagnose equipment condition.

This helps optimize maintenance intervals and predict replacement timing for efficient maintenance planning. -

RPM/Temperature Data Logging

We log and analyze key operational data such as RPM, temperature, and pressure in real time.

Based on load changes and operating patterns, we identify performance degradation factors and support objective maintenance decisions.

03

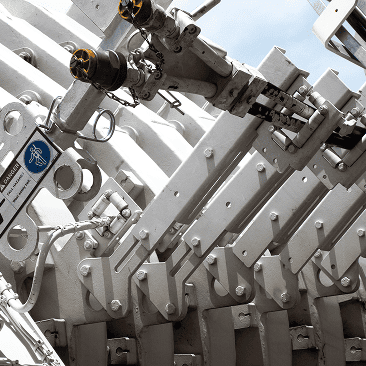

Hydraulic Repair

Professional repair and performance restoration for marine hydraulic systems.

We manage all components from pumps and cylinders to hydraulic valves.

Hydraulic Services

-

Hydraulic Pump Repair

We diagnose wear, pressure loss, and leakage, and replace/repair key components.

We restore output efficiency and ensure stable hydraulic supply for marine equipment. -

Hydraulic Cylinder Repair

We resolve piston leakage, seal damage, and stroke issues and overhaul with new parts.

We verify pressure retention and operational stability through on-site testing. -

Valve & Control Unit Repair

We accurately diagnose and restore failures in solenoid, check, and flow-control valves.

We improve flow imbalance and pressure instability to enhance overall hydraulic system efficiency. -

Hydraulic Hose/Line Replacement

We replace aged hoses and piping and improve leakage points.

We prevent safety incidents and minimize pressure loss in the system.

Diagnostic Techniques

-

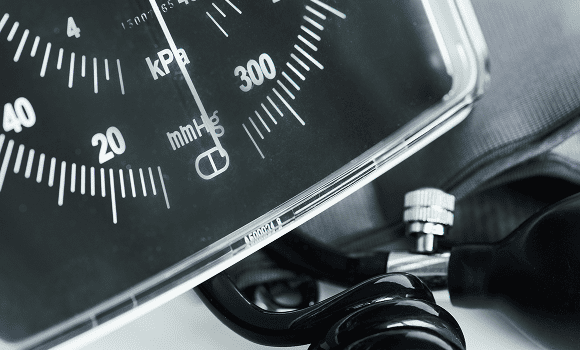

Pressure Test

We measure pressure at each point in the system to identify performance degradation areas and leakage.

-

Leak Detection

We use thermal and ultrasonic equipment to quickly detect external and internal leaks.

-

Oil Condition Analysis

We analyze viscosity, contamination, and oxidation of hydraulic oil to diagnose wear and failure risks.

04

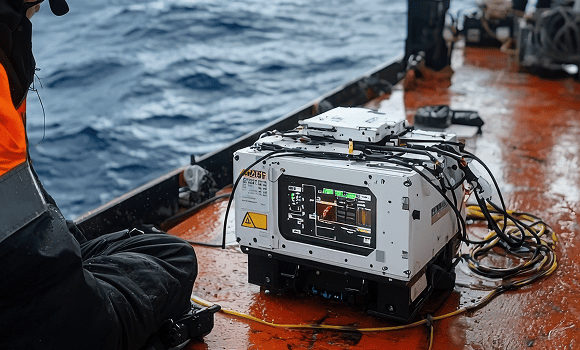

On-site Technical Support

To resolve unexpected failures and troubles quickly,

our engineers dispatch directly to ports, anchorages, and shipyards.

Key On-site Support Services

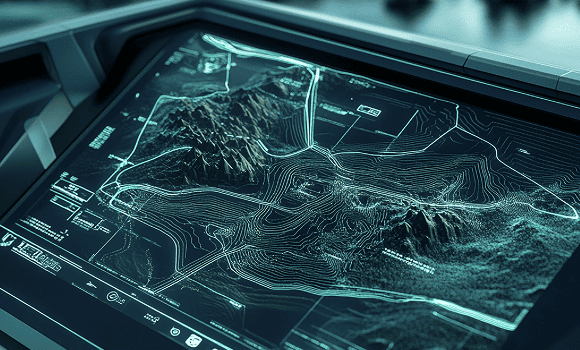

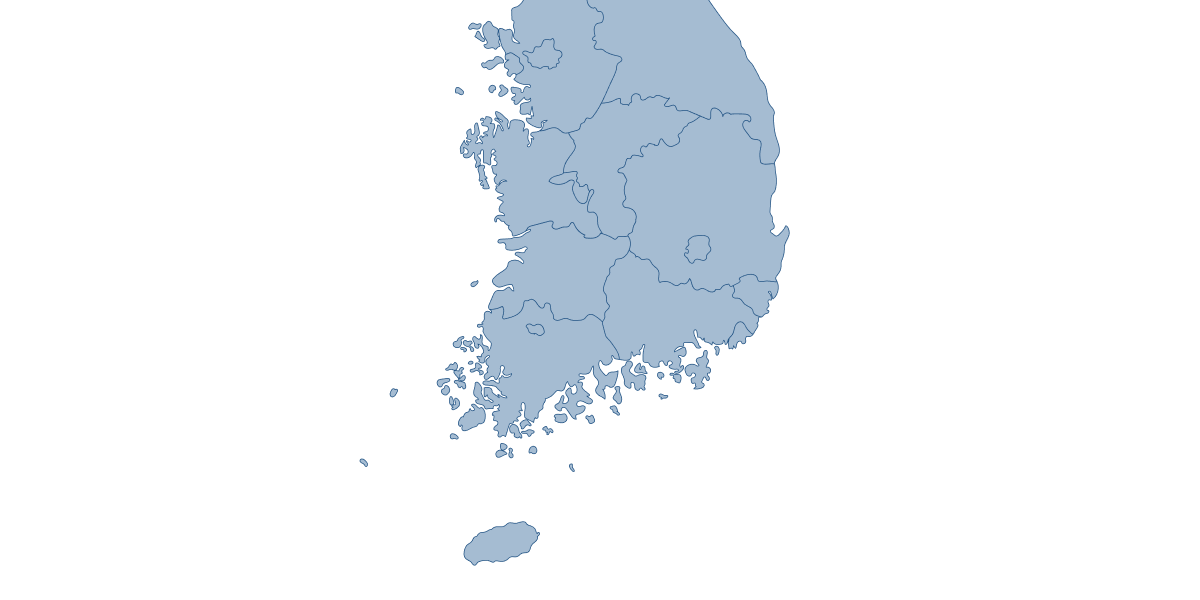

Service Coverage

-

Major Domestic Ports

- Busan

- Ulsan

- Pohang

- Gwangyang

- Yeosu

- Incheon

- Pyeongtaek

-

Overseas Support

- Major Ports in Southeast Asia

- China · Hong Kong · Taiwan

- Selected Ports in the Middle East

- Technical support via partner networks in Europe